Basic Information of Sublimation Paper

What’s sublimation paper?

Sublimation transfer paper is a type of specially coated paper used in the dye-sublimation printing process. Dye-sublimation printing is a method that allows for the transfer of high-quality, full-color images onto various materials, such as textiles, ceramics, metals, and more.

How the sublimation transfer process works:

Printing:

The desired image or design is digitally printed onto the sublimation transfer paper using specialized sublimation inks. These inks are formulated to transform into a gas when exposed to heat.

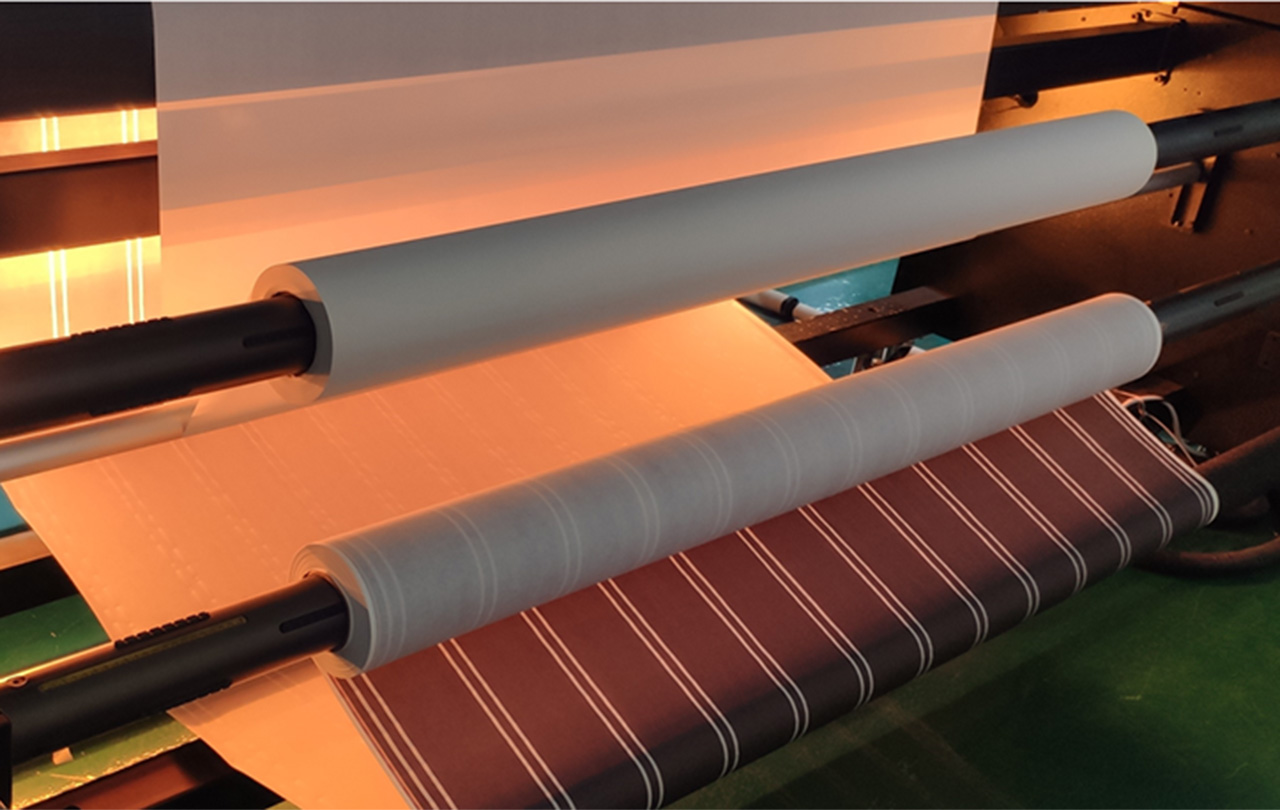

Transfer:

The printed sublimation paper is then placed in contact with the material to be printed, such as a polyester fabric or coated substrate.

Heat Press:

The assembly (paper and material) is subjected to heat and pressure using a heat press machine. The heat causes the sublimation inks on the paper to transition directly from a solid to a gas without becoming a liquid.

Sublimation Process:

As the inks turn into a gas, they penetrate the pores of the material's surface. Once the material cools, the gas reverts to a solid state, permanently embedding the ink into the material.

The key features of sublimation transfer paper:

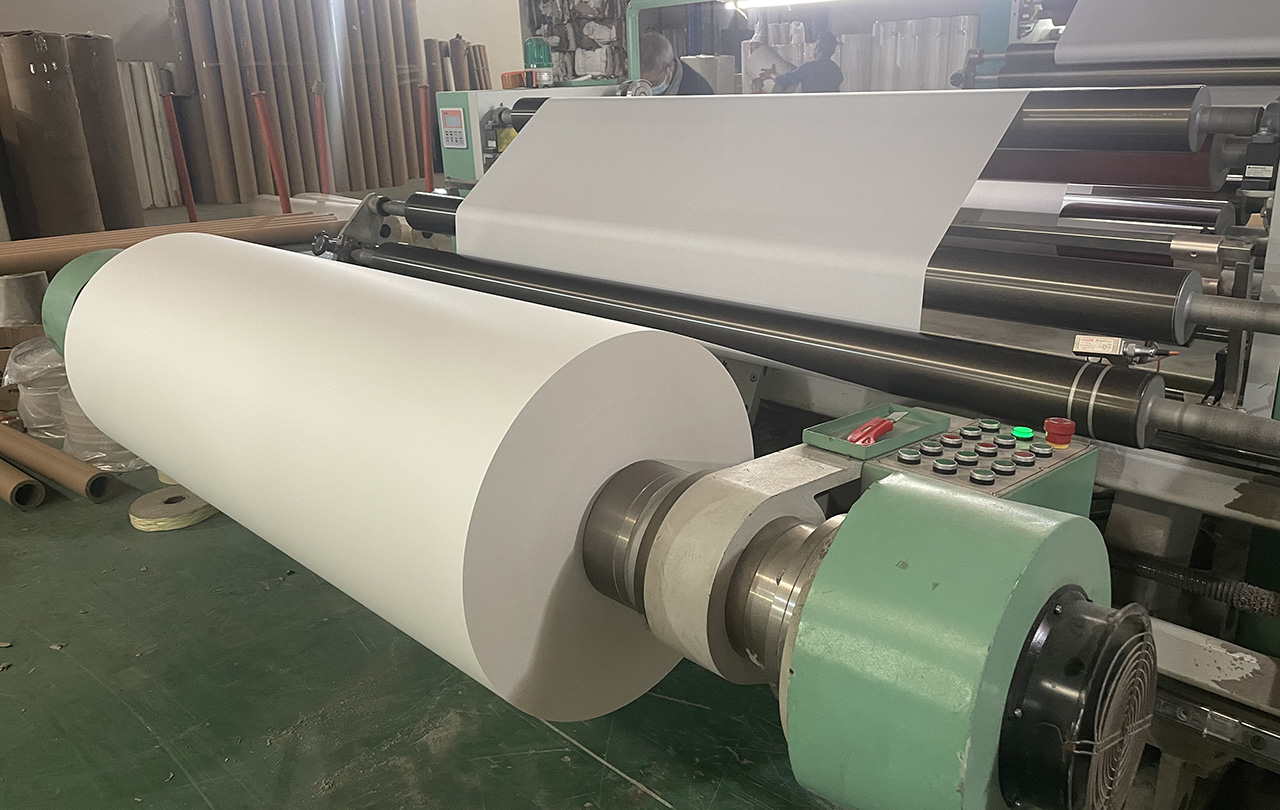

Coating: The paper is coated with a special chemical layer that facilitates the absorption and release of sublimation inks during the printing process.

High Ink Absorption: Sublimation transfer paper is designed to quickly absorb and hold the sublimation inks, ensuring vibrant and sharp prints.

Dimensional Stability: Properly coated sublimation paper maintains its flatness during the printing and heat press process, preventing image distortion.

Compatibility: Sublimation transfer paper is primarily used for materials with a polyester base or those with a special coating that can effectively bond with sublimation inks.

This printing method is popular for creating high-quality, durable, and full-color prints on a variety of products, making it common in applications such as apparel decoration, promotional products, personalized gifts, and more.

Longevity Key of store sublimation transfer paper

Proper storage of sublimation transfer paper is a decisive factor in the service life and quality of the paper. Below we share some storage tips:

1. Original Packaging:

This term refers to the initial packaging in which the sublimation transfer paper is factory-sealed. Original packaging helps maintain the paper's integrity, shielding it from environmental factors such as moisture and dirt.

2. Cool, Dry Place:

A cool, dry place implies storing the transfer paper in an environment with moderate temperatures and low humidity. Exposure to excessive heat or moisture can compromise the flatness and quality of the paper.

3. Sealed Packaging:

Sealed packaging involves resealing the paper's original packaging after it has been opened. This is crucial to prevent the paper from absorbing moisture, which could adversely impact the printing results.

4. Flat Storage:

Storing sublimation transfer paper flat means keeping it in a position where it remains level and does not curl or deform. This is important to ensure consistent print quality.

5. Shelf Life:

The shelf life of sublimation transfer paper refers to the duration during which the paper is guaranteed to maintain its optimal quality. Using the paper within its specified shelf life helps achieve the best results in terms of both color vibrancy and overall performance.

6. Print Quality:

Print quality is a measure of how well the sublimation transfer paper performs in producing vibrant, clear, and durable prints. Following proper storage guidelines enhances print quality by preserving the paper's characteristics.