Definition and Cautions of Sublimation Heat Transfer

What is sublimation heat transfer?

Sublimation transfer is a digital printing technology that transfers an image or design from paper to fabric. The technology is achieved using hot ink and a heat press.

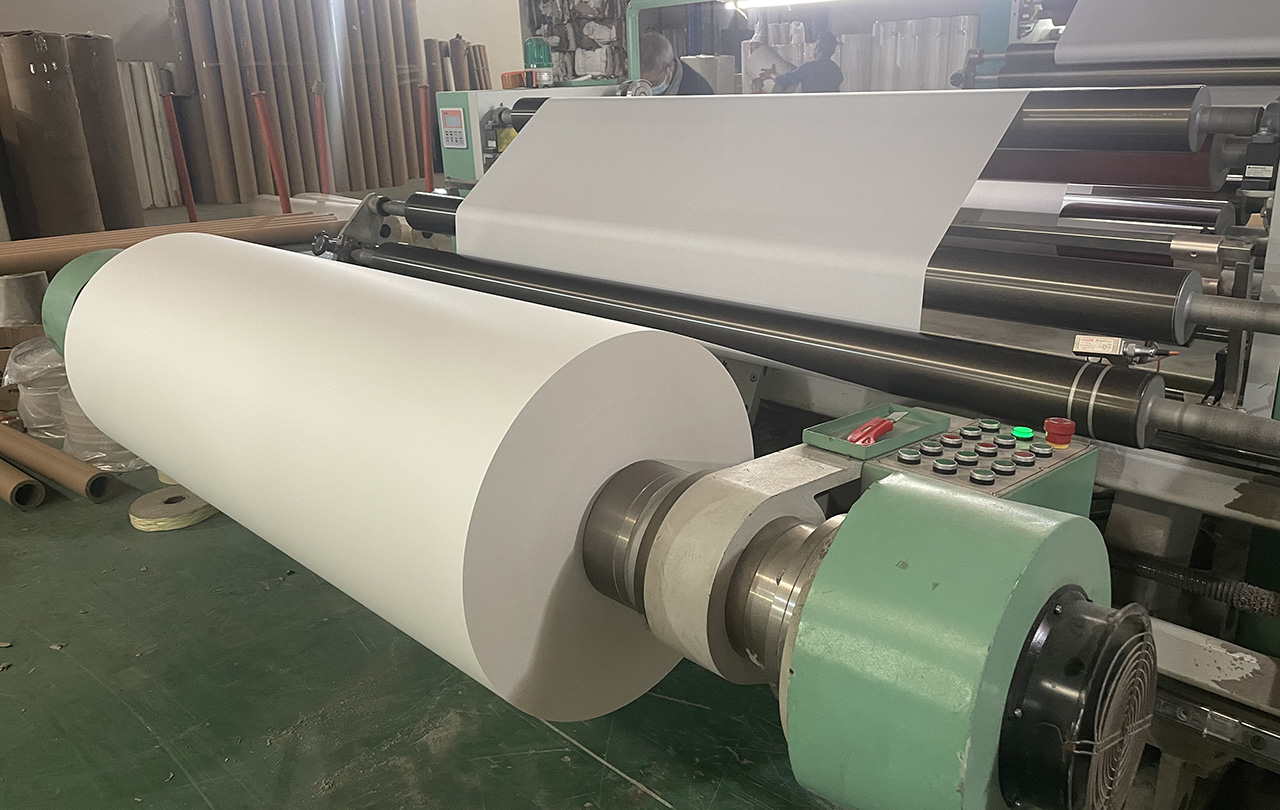

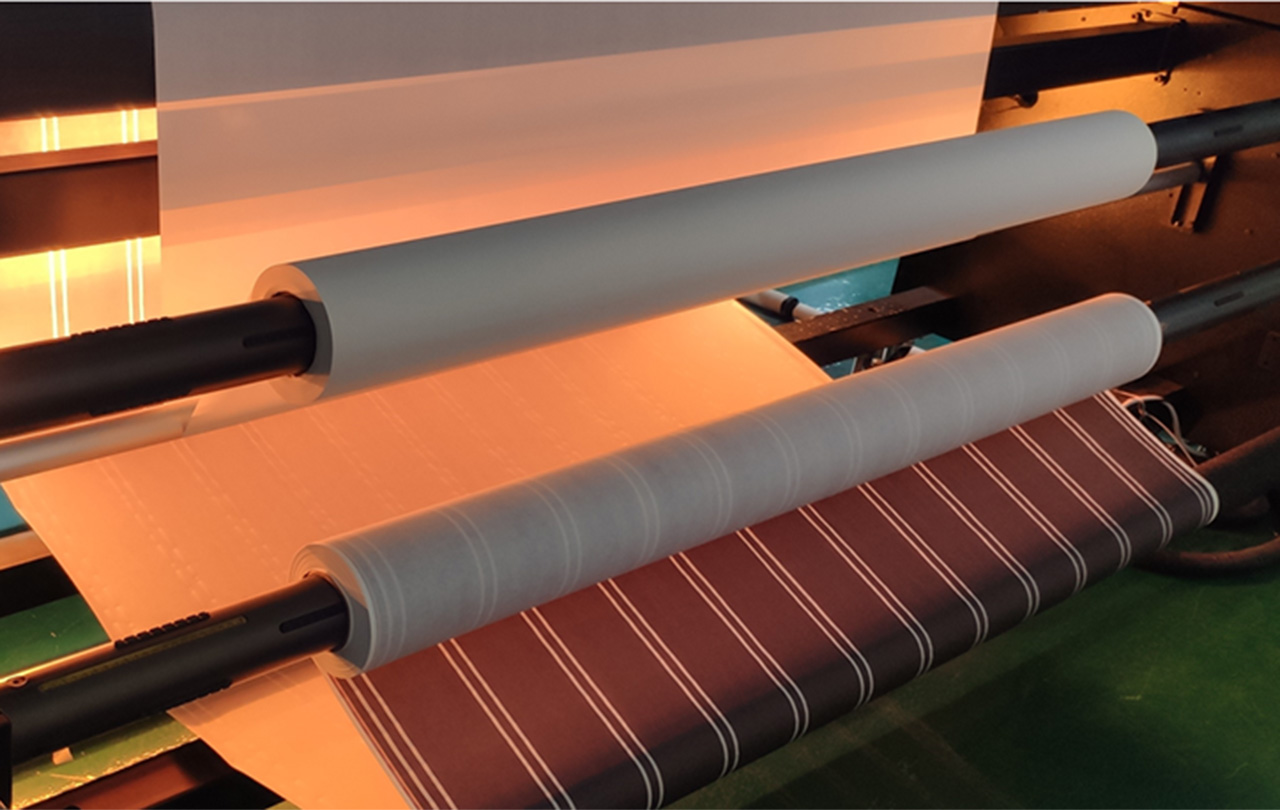

First, the image or pattern is printed on sublimation paper, and then the paper is placed in close contact with fabric. The sublimation paper and fabric together roll into the heat transfer machine, whose working temperature at around 220 degree centigrade. At high temperatures, the ink molecules changes directly from solid to gaseous state, and then penetrates into the fibers of fabric. When the temperature decreases, the ink re-solidifies and bonds to the fibers, forming a lasting image or pattern.

During the sublimation transfer production process, you need to pay attention to the following issues:

--- Choose the right type of ink for sublimation digital printing.

Sublimation digital printing requires to use special sublimation ink. This kind of ink is usually composed of pigments, resins and additives, and has the characteristics of stability at high temperatures and bright colors. Sublimation ink can be transferred to fabric or other materials under conditions of high temperature and pressure, and is fixed on the surface of the material after cooling. Common sublimation ink brands include Sawgrass, Epson, Ricoh, etc. Select the corresponding brand and model of ink according to the printer model used to obtain the best sublimation effect.

--- Heating Temperature and time control: Dye-sublimation transfer needs to be carried out within a certain temperature range. Too high or too low temperature will affect the transfer effect. The heat transfer temperature range is about 180-230℃, and heating time should be 10-30 seconds. Before bulk production, better to do testing first, to confirm the optimal process parameters. In addition, the temperature detector must be accurate, and operating staff should examine its condition regularly.

--- Pressure control:

During heat transfer, the printed sublimation paper and fabric must be close to each other. A certain amount of pressure needs to be applied when transferring, to ensure that the pattern on paper can be completely transferred to the fabric. Too high or too low pressure will affect the transfer effect, so it needs to be adjusted according to different materials and patterns.

--- Adjust the appropriate color intensity

If there is too much ink printed into the sublimation paper, it is easy to dry. So during testing before bulk production, need to adjust the best color concentration, to eusre best printing effect, as well as the transfer effect.

In short, during the sublimation transfer production process, it is necessary to pay attention to issues such as temperature, time, pressure, material selection, pattern design and preparation, etc, to ensure the quality and consistency of the transfer effect.