As one of the cores of the sublimation transfer process, printers are currently divided into three categories according to printing speed: low-speed, medium-speed and high-speed machines.

There is actually no clear definition between low-speed and medium-speed machines. Generally, printers with a full-width printing speed of less than 1 m/min are classified as low-speed machines; printers with a printing speed of 1 to 10 m/min are classified as medium-speed machines; printing speed Above 10 m/min are classified as high-speed machines.

1. Demand for sublimation transfer paper from low-speed scanning printers

Low-speed printers such as Mimaki JV33, Mutoh 1604, Invito, etc. have higher printing precision, and the printer structure is generally equipped with a paper pressure wheel. When printing with high inkjet volume, because the paper stays in the nozzle movement area for a relatively long time, the paper will swell and deform after absorbing the ink; and due to the pressure constraint of the paper platen wheel on the paper, the paper will deform obviously. The prism is arched, which can easily scratch the nozzle and damage the printed pattern. Therefore, for this type of printer, the wet deformation of the paper is required to be small, and the transfer paper coating is required to have a strong ability to carry ink.

2.Demand for sublimation transfer paper from medium-speed printers

Medium-speed printers are similar to Italian MS-JP4, MS-JP7, Tianjin Licai MICOLOR 5816. Compared with low-speed machines, such machines have several times higher printing speed. Generally, they do not have paper pressure rollers and rely entirely on roller tension. To adjust the paper operation, the printing speed is significantly accelerated. Although the drying interval is lengthened, it is obviously not enough relative to the increase in speed, so the paper drying speed is required to be higher.

3. Demand for sublimation transfer paper from high-speed printers

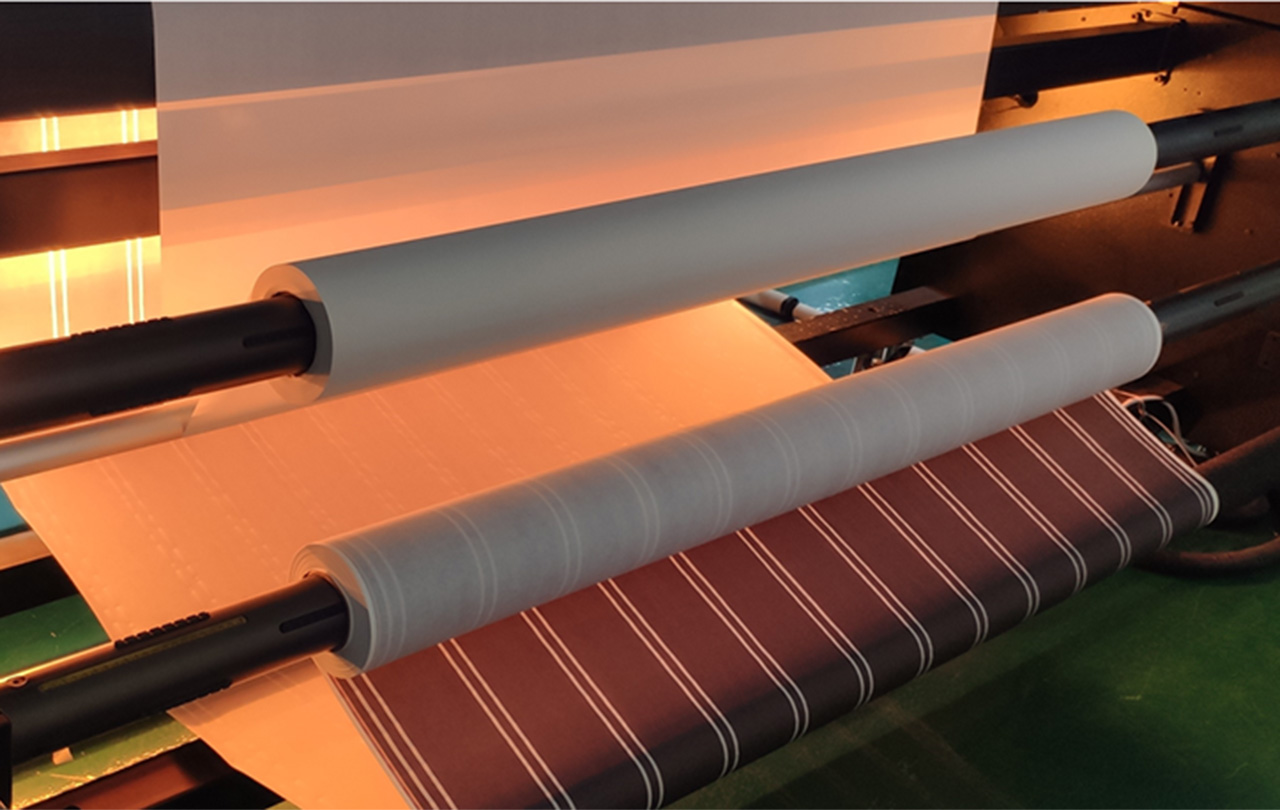

High-speed printers currently mainly refer to single-channel printers, such as One-Pass or Single-Pass printers that we often hear. The most obvious feature of this type of printer is that the nozzles are fixed in multiple rows and do not move during printing. Printing relies entirely on paper movement, and the printing speed is very fast, which can reach 30-80m/min. The length of the drying tunnel is generally more than 10 meters. In addition, the paper is adhered to the surface of the guide belt in the printing channel. The paper requirements of this type of printer are mainly as follows:

a. Good flatness: Most coated papers tend to warp after being baked at high temperatures, which is commonly known in the industry as "poor bending resistance" of paper. The drying tunnel of high-speed printers is long, and the paper needs to be baked at high temperature for a relatively long time in the oven. Therefore, the paper must have good flatness after being baked at high temperature.

b. Fast drying speed: Although the drying tunnel of high-speed printers has been lengthened, due to the faster paper running speed, heat source limitations, factory building limitations, etc., the paper itself still needs to have fast drying properties.

c.The peelability of the paper backing should be appropriate.

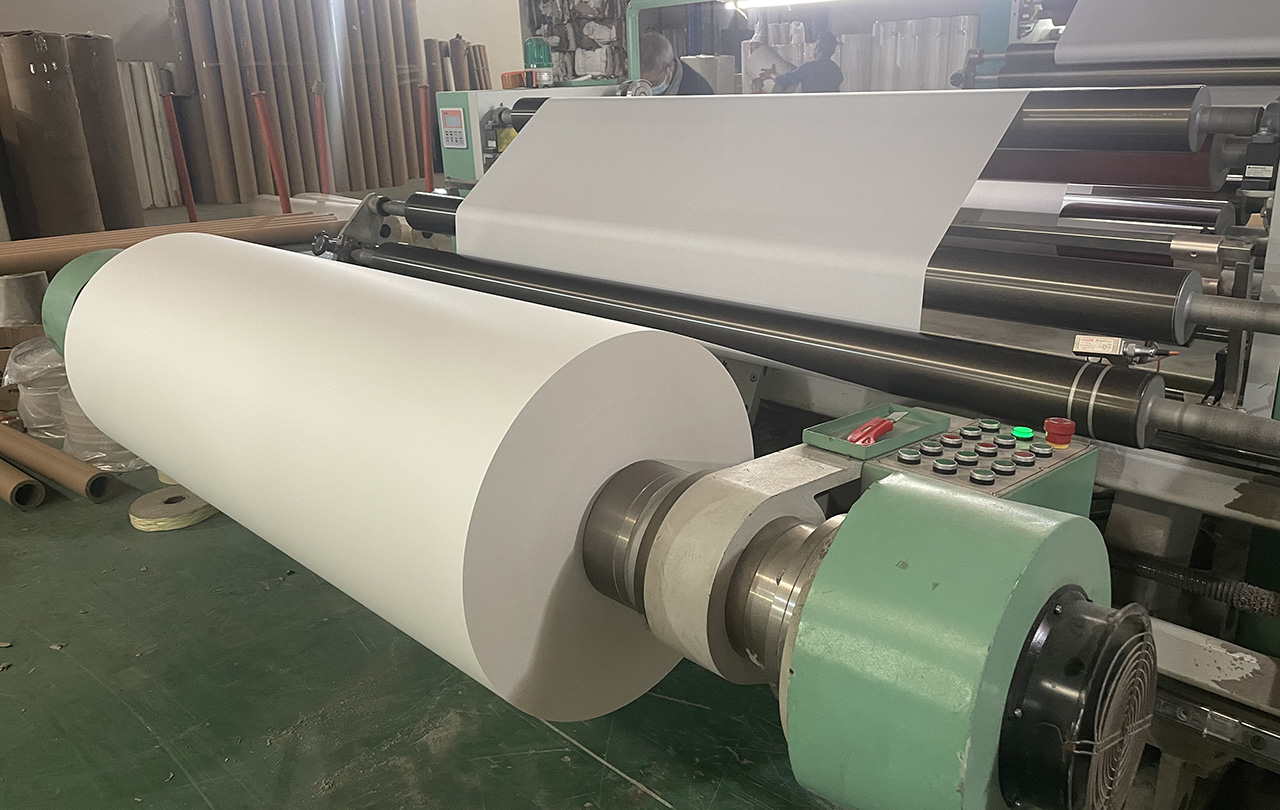

d.The paper should be thin: Due to the faster machine speed, thin paper is more suitable for large roll printing and high-speed thermal transfer, and can also significantly reduce costs.