Which is better to peel off the hot stamping film, cold tear film or hot tear film?

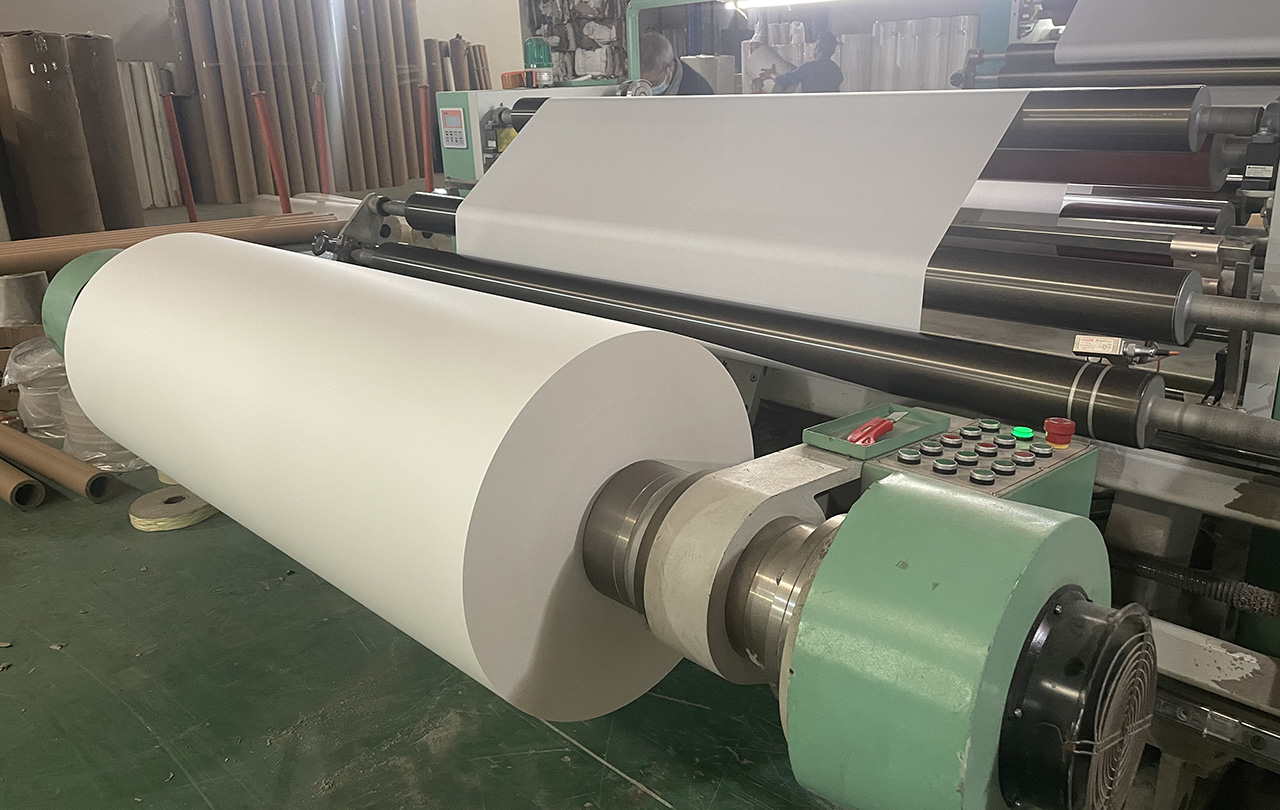

White ink heat transfer has a wide range of uses, and its technology and effects are constantly being updated. What remains unchanged is that when the heat transfer film is hot stamped on the substrate, the film needs to be peeled off to complete the entire hot stamping process. However, some heat transfer films need to be hot-teared, while others need to be cold-teared. Many customers will ask why this is? Which membrane is better?

Today, I will take you to have an in-depth understanding of the magic heat film.

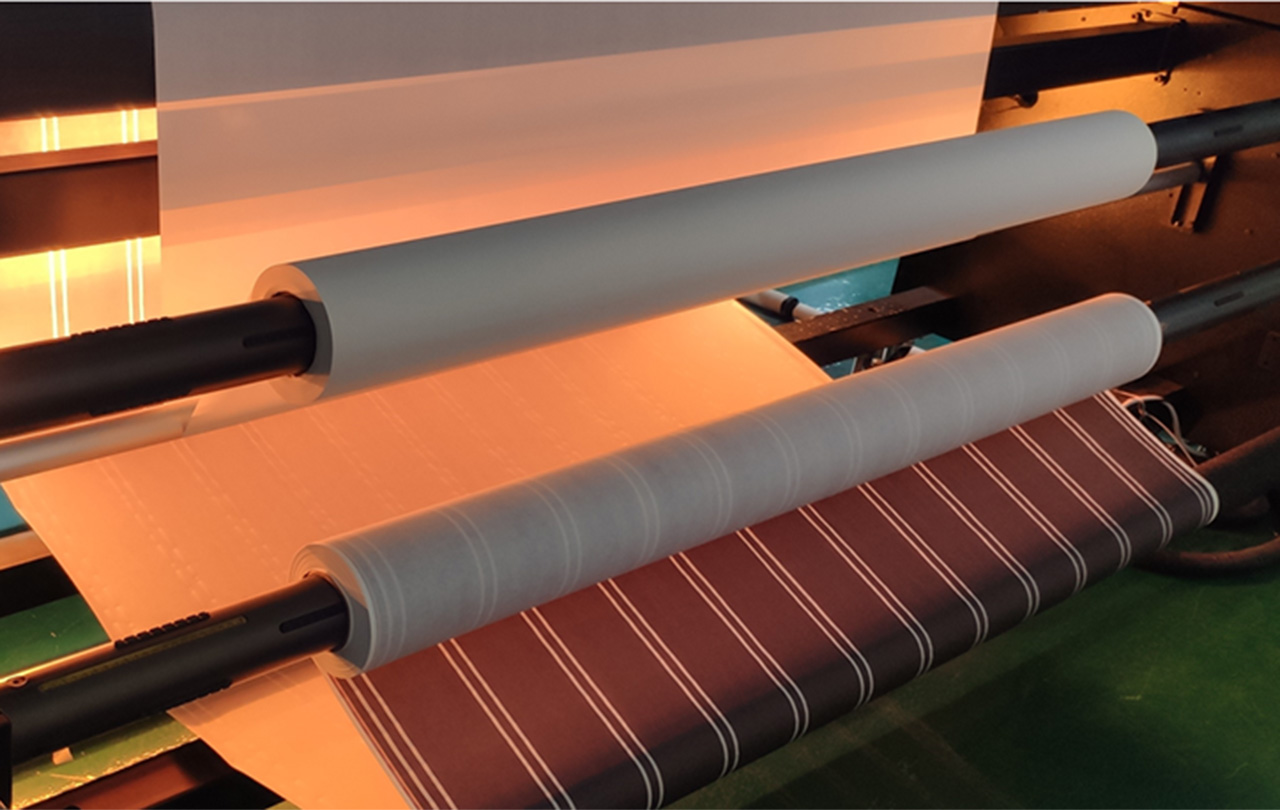

Hot-peel film

The main release component of hot tear film is wax, which has poor ink absorption performance and small letters are easy to fall off, but the surface becomes brighter after it is completely cooled.

After the hot stamping is transferred to the fabric by the ironing machine, it is torn off while it is hot, saving waiting time.

Tear it off within 9 seconds after turning on the press (ambient temperature 35°C), or tear it off when the film surface temperature is greater than 100°C.

If not peeled off in time, the cooling glue will stick to the clothes, causing the clothes and film to tear apart. There may be problems such as pattern residue.

Cold peel film

The main release component of the cold tear film is silicon, which has good product stability and a matte effect after thorough cooling.

Transfer first, cool down (below 55 degrees Celsius) and then gently peel off the film, otherwise there is a high risk of tearing off the hot pattern.

Difference between the two:

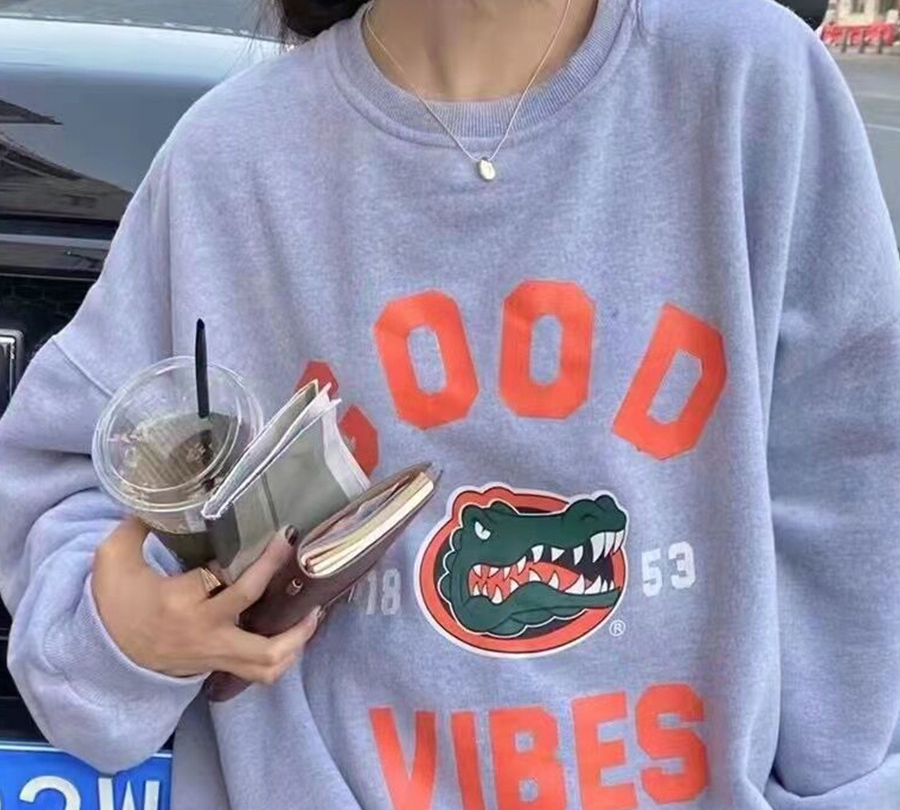

1. Color aspect

The color produced by hot-peel film is brighter and the color expression is stronger; the color produced by cold-peel film is matte and has a stronger texture.

2. Color fastness

The color fastness of the two is almost the same, and both can reach level 3 or above of washability.

3. Pressing requirements

Hot tear film has relatively detailed requirements on pressing time, temperature, pressure, etc. Generally speaking, hot tearing can be easily achieved at 140-160 degrees, pressure 4-5KG, and pressing for 8-10 seconds. The cold tear film has relatively lower requirements.

4. The difference in pulling force

Neither of them will have tensile bursts after hot pressing.

5. The difference in efficiency

If you are pursuing efficiency, you can choose hot-tear film. Cold-tear film is easier to tear when it needs to be lukewarm or cool.